85% of industry customers choose

Widely used in various industries

In Vitro Diagnostics Industry

Synthetic Biology

Medical Devices

Medical Beauty Skin Care

Food, Beverages, Daily Necessities

Automotive Electronics

Main Business

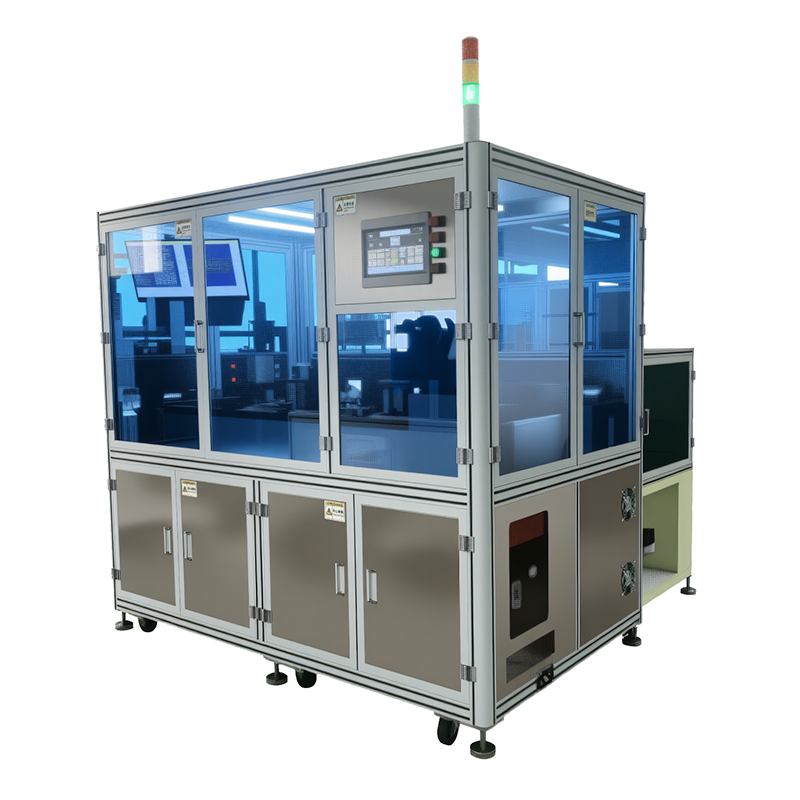

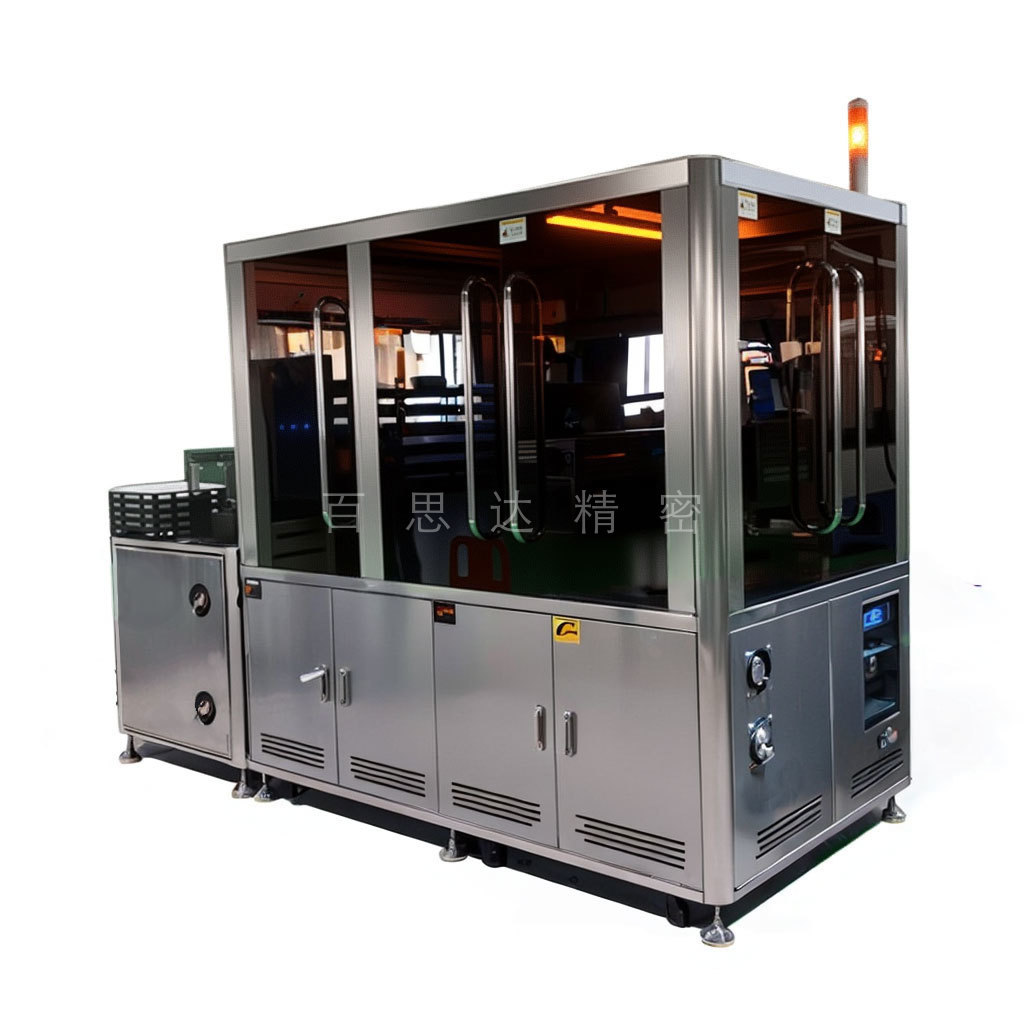

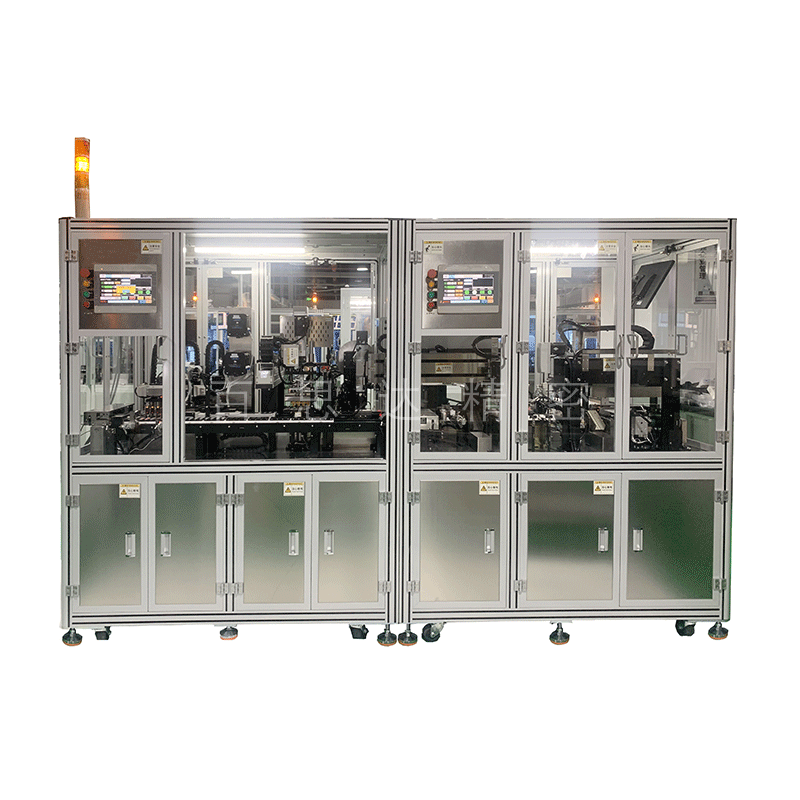

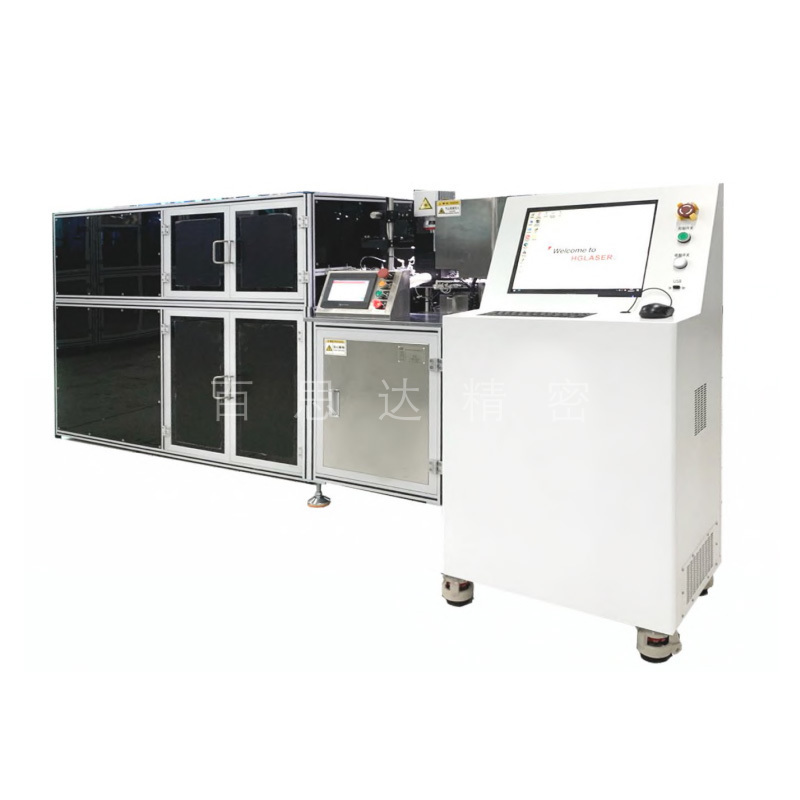

Relying on the best vision application platform, with artificial intelligence and visual detection as the core, the deep integration of intelligent control, machine vision and deep learning technology to build a machine vision algorithm library.

In response to the needs of industries such as compound synthesis and surface defect detection of industrial products, Best has set up upper computer software technology, which integrates CV and NLP algorithms including upper technology, database communication, marking identification, liquid measurement and identification calculation and other cash technologies, aiming at effectively solving industry pain points with industrial-grade high-precision in-depth learning algorithms.

Lightweight, reliable, intelligent, clean different configurations of the robot series products, flexible for life and health, integrated circuit manufacturing and other sensitive environment.

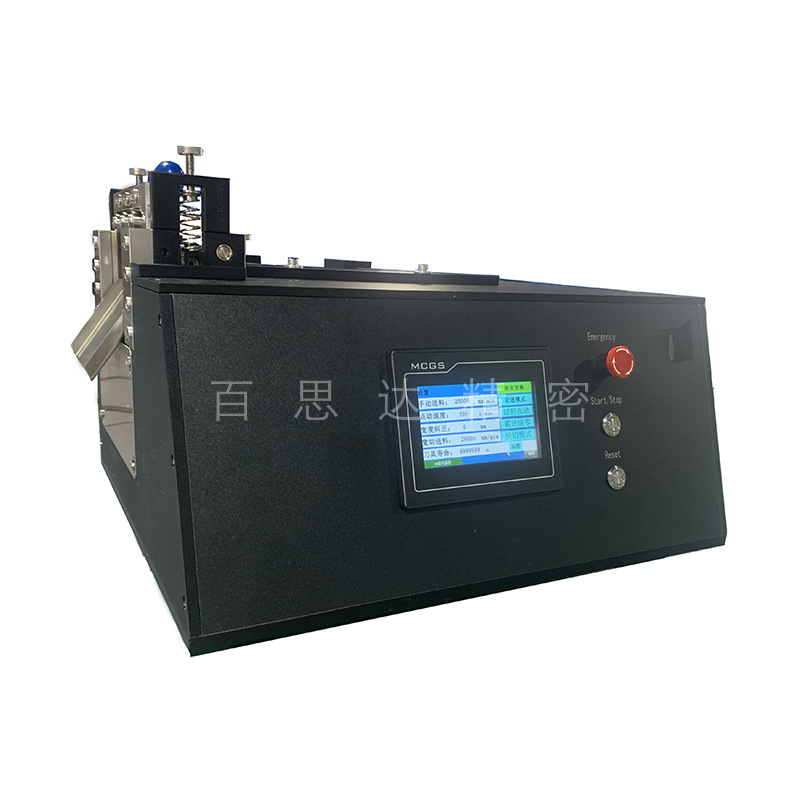

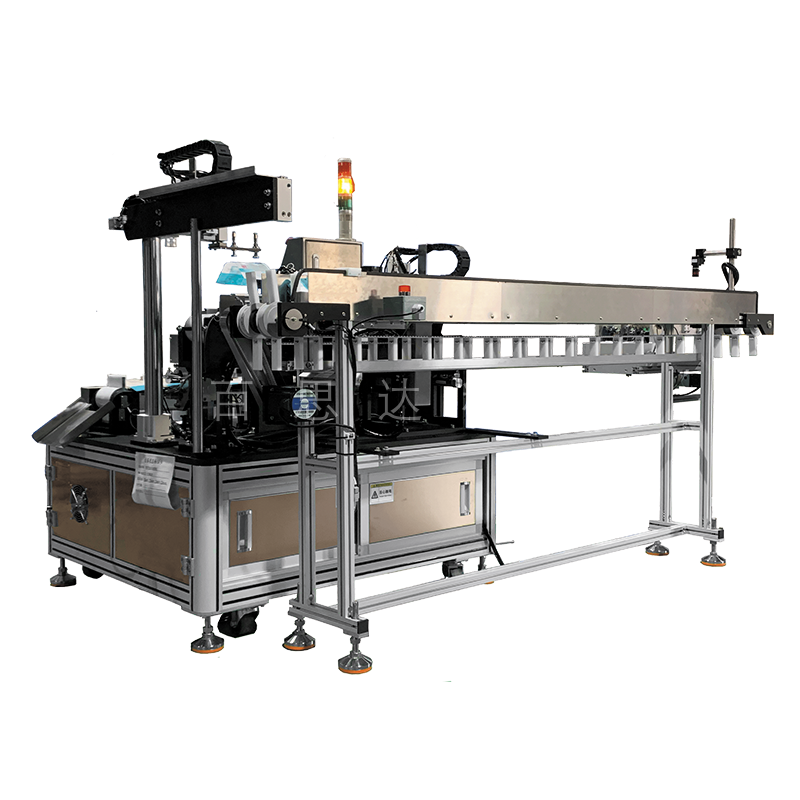

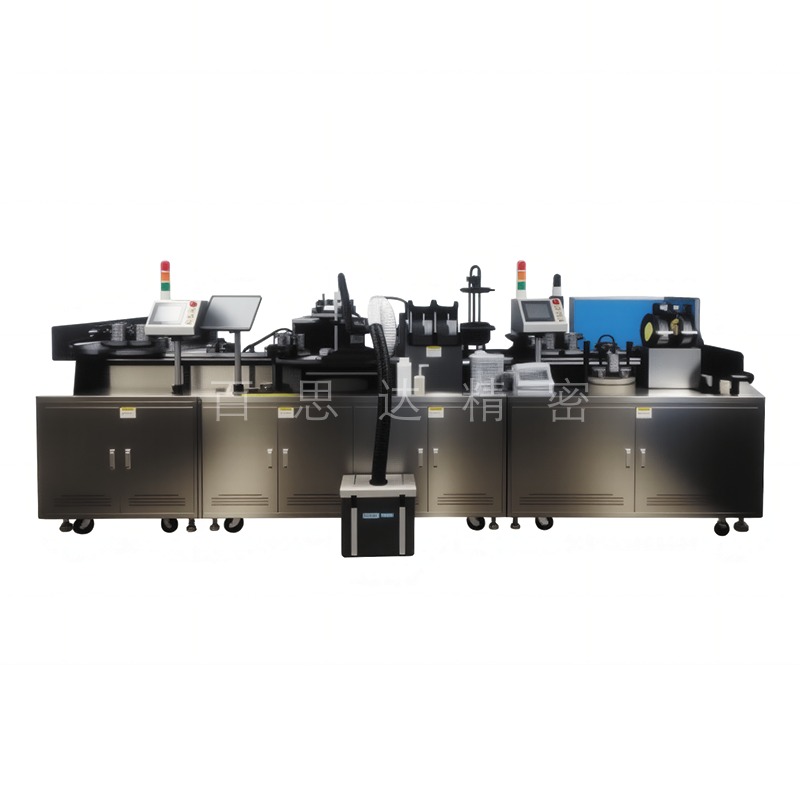

Liquid Filling Instrument Processing Technology

In order to meet the diverse needs of customers, Best has independently developed various types of liquid tube filling technology solutions, and at the same time, it is constantly iteratively updated to better serve customers in beauty, food, in vitro testing and other industries.

About Us

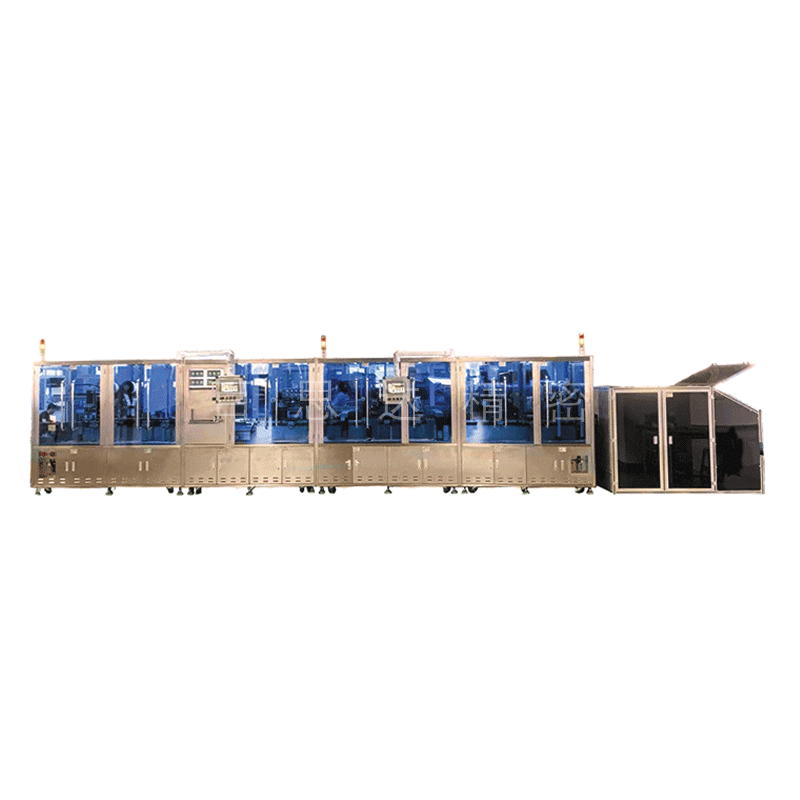

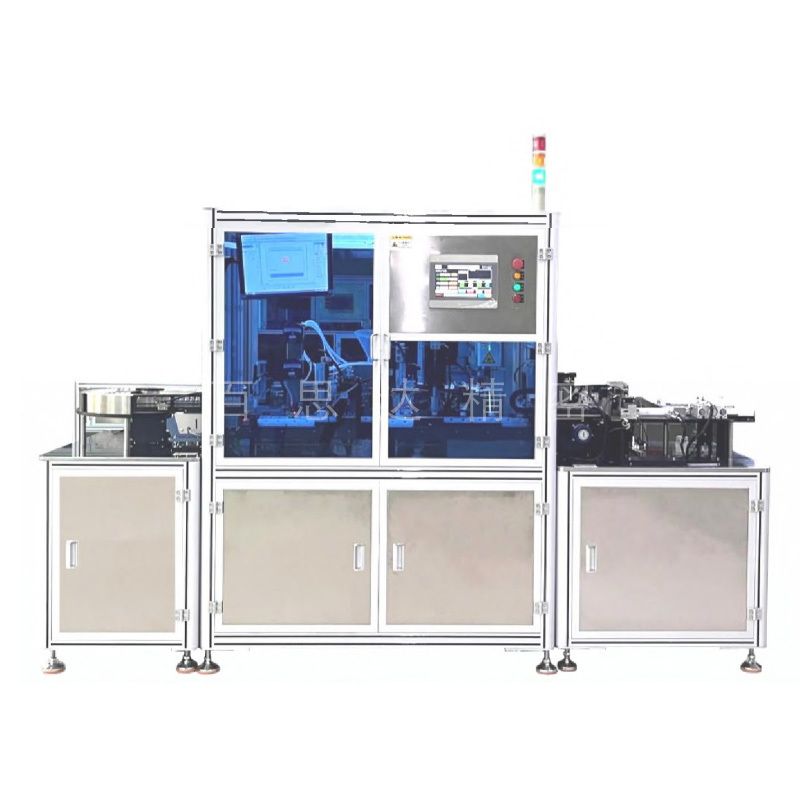

Huizhou Bestam Precision Machine Co., Ltd. is a technology company specializing in the research and development, design and manufacture of industrial automation production equipment, and providing customers with overall manufacturing solutions. Since its establishment in June 2008, the company has always adhered to the concept of "professionalism, focus, service, and win-win" to provide customers in various industries with professional, high-quality, efficient and guaranteed automation solutions; through years of unremitting efforts, it has won The general recognition and high trust of our customers.

Since 2012, Best Precision has been committed to the research and development and production of automatic equipment such as assembly, packaging, testing, automatic marking of POCT, IVD quick diagnosis device, biochip and other products, and has achieved rich results.

-

15

+Company Establishment

-

160

+Covered cities

-

180

+Clients

-

3500

+Shipping equipment

Partners

News

05

2025-11

Precision is power: Precision Filling Equipment with Three-Way Valves

09

2025-10

09

2025-10

05

2025-08

Leave a message online

Provide you with one-to-one exclusive service