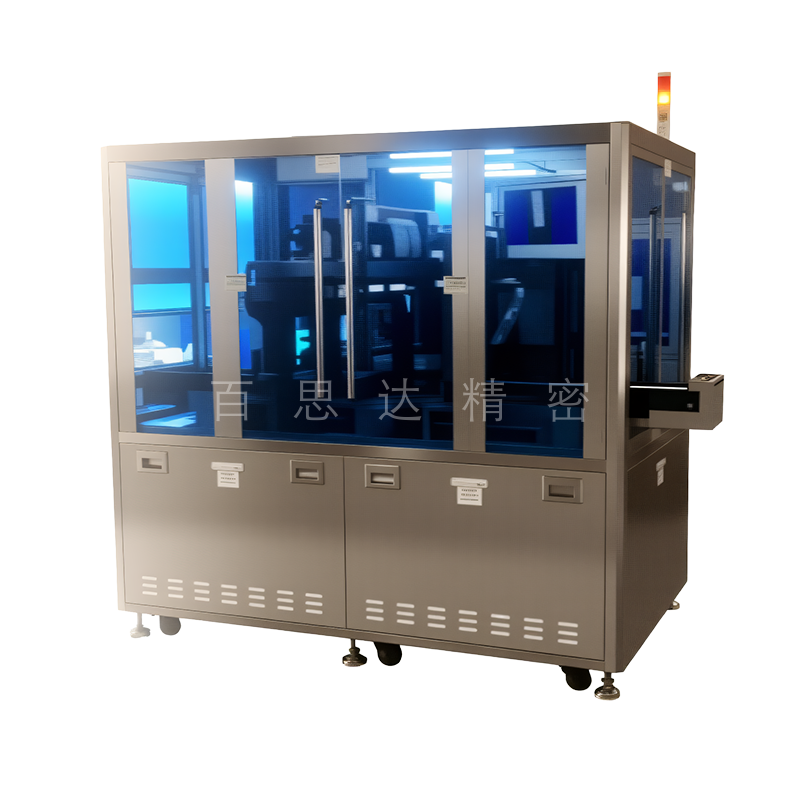

Precision is power: Precision Filling Equipment with Three-Way Valves

Release time:

2025-11-05 14:12

Source:

Traditional filling equipment has always faced three major challenges when handling high-viscosity and corrosive fluids: wall-adhesion losses erode product profits, fluctuating precision lowers yield rates, and cross-contamination poses significant quality-control risks. However, the three-way valve automatic filling system—anchored in its advanced layered dynamic filling technology—redefines the standards for complex fluid handling. It’s as if equipping both laboratories and production lines with a "fluid GPS," ensuring that every drop of colloid, lysis solution, or biological reagent reaches its intended destination with pinpoint accuracy. With layered filling, say goodbye to "filling anxiety" once and for all!

https://www.hzbestam.cn/product_detail/17.html

Core Technology: Industrial Aesthetics with Precise Control of Quantity

Multidimensional Precision Filling System

1. Motion Positioning System

Equipped with a high-precision chain plate transmission mechanism and fitted with a displacement sensor, it achieves a positioning accuracy of ±0.1mm per station.

2. Tripartite Collaborative Filling System

High-viscosity material unit: Equipped with a high-precision screw valve, achieving an accuracy of ±3% when dispensing volumes between 100 and 250 μl.

Corrosive Liquid Unit: Equipped with a self-calibrating peristaltic pump, the lysis solution filling volume is 0.8–1.4 ml with an error of ≤±5%.

Precision Fluid Cleaning Unit: Employs a ceramic pump to thoroughly remove residual liquids from within the tubing, ensuring consistent filling accuracy.

3. Intelligent Sealing Film System

① An integrated heat-sealing and die-cutting composite mechanism is used to produce heat-sealing film sheets with neat, wire-free edges; the positioning accuracy of the die-cut sheet edges is ±0.05mm.

② Perform secondary positioning on the product’s shape to eliminate accumulated errors, achieving a product positioning accuracy of ±0.05mm.

Intelligent Visual Filling Compensation System

The Visual Intelligence Filling Compensation System—more adaptable and responsive than ever! The visual inspection system dynamically calculates the filling workload in real time, based on the gaps within the three-way valve’s filling chamber and variations in the height of incoming materials—and then converts this into the corresponding volume of liquid to be filled.

Typical application scenarios

It is suitable for multi-liquid layer filling and offers significant advantages in products used for in vitro diagnostics, synthetic biology, and pre-filled tubes.

Press recommend

WHX Labs 2026 | The First Exhibition of the Year—A Wonderful Start

From February 10 to 13, 2026, the Arab International Medical Laboratory Instruments and Equipment Exhibition (WHX Labs) will grandly open at the Dubai World Trade Center in the United Arab Emirates. As the largest laboratory equipment event in the Middle East, this year’s exhibition brings together over 800 leading medical enterprises from more than 40 countries worldwide, once again demonstrating its status as an authoritative benchmark for technological innovation and industry trends in the global IVD sector.

The packaging and bagging process for traditional medical anesthesia masks has long been plagued by four major issues: bags sticking together, difficulties in automated bag retrieval, high rates of bag damage during insertion, easy detachment of UDI codes, and uneven sealing strength leading to compromised air-tightness. Each defective mask packaging not only erodes the already slim profit margins of enterprises but also increases the risk of product traceability and reduces the yield of good-quality products every time a UDI code comes loose or a sealing failure occurs. Moreover, every single handling step further diminishes production capacity.

Time flies, and the first month of 2026 has quietly arrived, bringing with it the warmth of the New Year. Looking back at the year 2025 that we’ve just bid farewell, as the challenges and opportunities in the IVD industry have intertwined and settled over time, we’ve chosen to embark on a heartwarming journey of gratitude and growth in Ganzhou, the ancient Song Dynasty city steeped in history. This is not merely a simple trip; it’s a carefully planned reunion of souls—a chance for us to rediscover the true meaning of partnership and gather the strength needed to move forward, amidst the green bricks and dark-tiled roofs of this ancient city and atop the misty peaks of Sanbai Mountain. As all things embrace renewal, let us unite our energies and set forth together.

Why is everyone promoting production equipment for standard card-type test cards, yet rarely mentioning equipment designed for pen-type test cards? That’s because pen-type test card production machines demand significantly higher technical expertise. Standard card-type equipment uses a simple, flat fixture arranged in a single line, while pen-type cards feature highly varied curved surfaces with dramatic differences in curvature—requiring precise alignment that must be achieved instantly to prevent gaps from forming. Moreover, the feeding process for pen-type cards is prone to misalignment, often leading to material stacking or even machine jams. And here’s another challenge: traditional 2D vision systems rely solely on "flat templates," so when they encounter the reflective surfaces or gradually changing patterns of pen-type test cards, they quickly "lose sight" altogether, resulting in a defect detection rate that starts at 2% or higher.

Jointly exhibiting at MEDICA 2025 in Germany—shining brightly on the international stage

On November 17, the world's most prestigious international medical event—the MEDICA 2025 International Medical & Healthcare Exhibition in Düsseldorf, Germany—began with a dazzling opening along the picturesque banks of the Rhine River.

Exhibition Preview | Bestam sincerely invites you to attend the MEDICA trade fair in Germany!

From November 17 to 20, 2025, MEDICA, the global benchmark for the medical industry, will make a grand debut in Düsseldorf. As a national-level high-tech enterprise specializing in precision manufacturing of biomedical machinery for 17 years, Huizhou Bestam Precision Machine Co., Ltd. will showcase its cutting-edge in-vitro diagnostic technology solutions for the first time—stepping onto the international stage as a service provider (Hall 3, Stand H14)—and proudly present China’s “Made-in-China” innovation achievements, backed by 17 years of meticulous craftsmanship.