With a favorable tide and fair winds, Bestam makes its debut at CMEF, contributing to a new upgrade in the medical packaging field

Release time:

2025-04-09 11:52

Source:

On April 8, 2025, the 91st China International Medical Equipment Fair (CMEF) opened grandly in Shanghai. As an important platform for innovation and cooperation in the medical industry, this exhibition brought together global medical elites, with nearly 5,000 brand enterprises showcasing tens of thousands of products, comprehensively demonstrating the latest achievements of the medical and health industry.

01

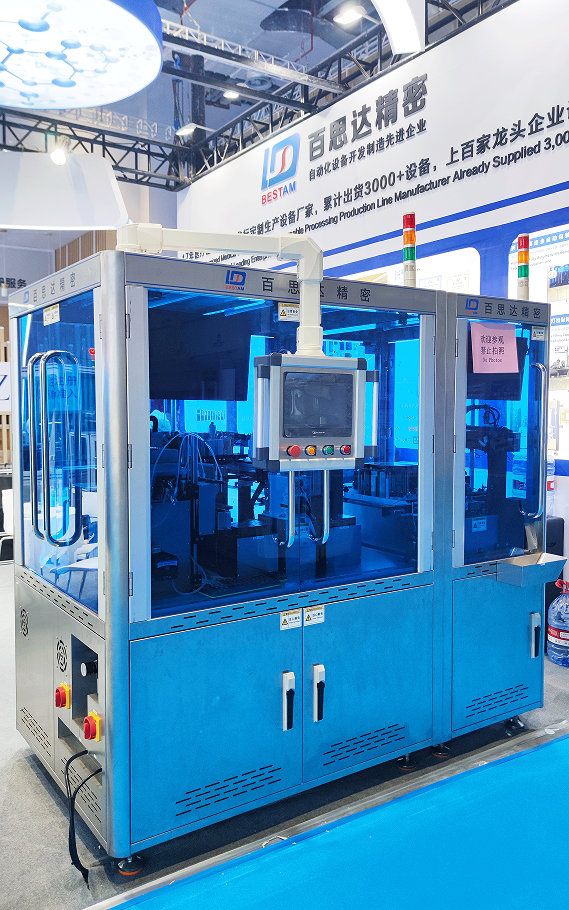

Automated equipment debuted at the exhibition

Digital Technology Summit

Huizhou Baisida Precision Machinery Co., Ltd., as an innovative enterprise in the field of medical equipment manufacturing, participated in this exhibition to showcase its technological strength and innovative achievements in the field of medical equipment manufacturing. The company showcased several impressive pieces of equipment, including a fully automatic strip cutting, bagging, and sealing machine; a microfluidic disc chip laminating device; and a filling, sealing, capping, and labeling device, attracting many industry partners to stop and exchange ideas.

Fully automatic strip cutting, bagging, and sealing machine

This is one of our quite mature equipment models, It performs particularly well in terms of efficiency. For strip cutting, card loading, and bagging equipment, our production capacity can reach 4000 Pcs/h, which is higher than the industry standard. We can achieve the production capacity that our peers can only achieve with a 3-channel or 4-channel design by adding a channel, not only saving the expensive GMP workshop floor space, but also reducing the operating cost of the customer's workshop, and also solving the problem of increased difficulty for operators due to the large size of the equipment. Through key technologies and ingenious structural design, this equipment can achieve compatible production of multiple board widths, multiple dose strip widths, and multiple Specification bags. Product model changes are convenient and fast, greatly improving production efficiency and flexibility. The equipment is compatible with various Specifications, including board width, dose strip width, and bag size, to meet different production needs. The operating experience is excellent, simple and easy to use, providing users with a highly efficient and convenient production experience.

At the same time, we have also developed precise NC film cutting technology, minimizing the influence of blade adhesive, effectively avoiding the situation of film adhesion inside the machine, significantly reducing the number of shutdowns caused by cleaning, and thus indirectly ensuring the stable output of production capacity, ensuring efficient and smooth production process.

In addition, we can also print, engrave, or hot stamp product date codes on the product bags produced by the equipment, realizing product traceability and enhancing product quality and safety.

Microfluidic disc chip laminating equipment

The disc structure of the microfluidic chip has extremely high requirements for lamination accuracy. If the equipment cannot achieve precise alignment or channel sealing, it may lead to liquid leakage or channel blockage. To this end, we are equipped with a 5-megapixel high-precision vision system to perform real-time detection of pressure-sensitive film angle positioning, coding, label presence, and label position. At the same time, a precision pressure gauge is used to monitor the pressure-sensitive film rolling pressure value in real time and record the output table to ensure that the channels are not damaged during production and that high-quality products are produced.

Filling, sealing, capping, and labeling equipment

The filling, sealing, capping, and labeling equipment integrates multiple advanced functions, providing an efficient and precise solution for medical dispensing. This equipment supports multiple dispensing methods, including peristaltic pump dispensing, injection pump dispensing, metering pump dispensing, and pipette dispensing, to meet different production needs. At the same time, the equipment is equipped with a weighing function to check the filling amount in real time to ensure filling accuracy. After filling is completed, it will automatically perform sealing and (or) capping operations to ensure the sealing and stability of the product. We have also configured a CCD detection system for this equipment, which can detect impurities in the reagent in real time and monitor the liquid level height to ensure product quality. Online coding and labeling functions further improve the automation level of the equipment, supporting precise label attachment and automatic identification to ensure the accuracy and traceability of product information. Finally, the equipment completes product conveying through an intelligent feeding system to ensure an efficient and reliable entire production process.

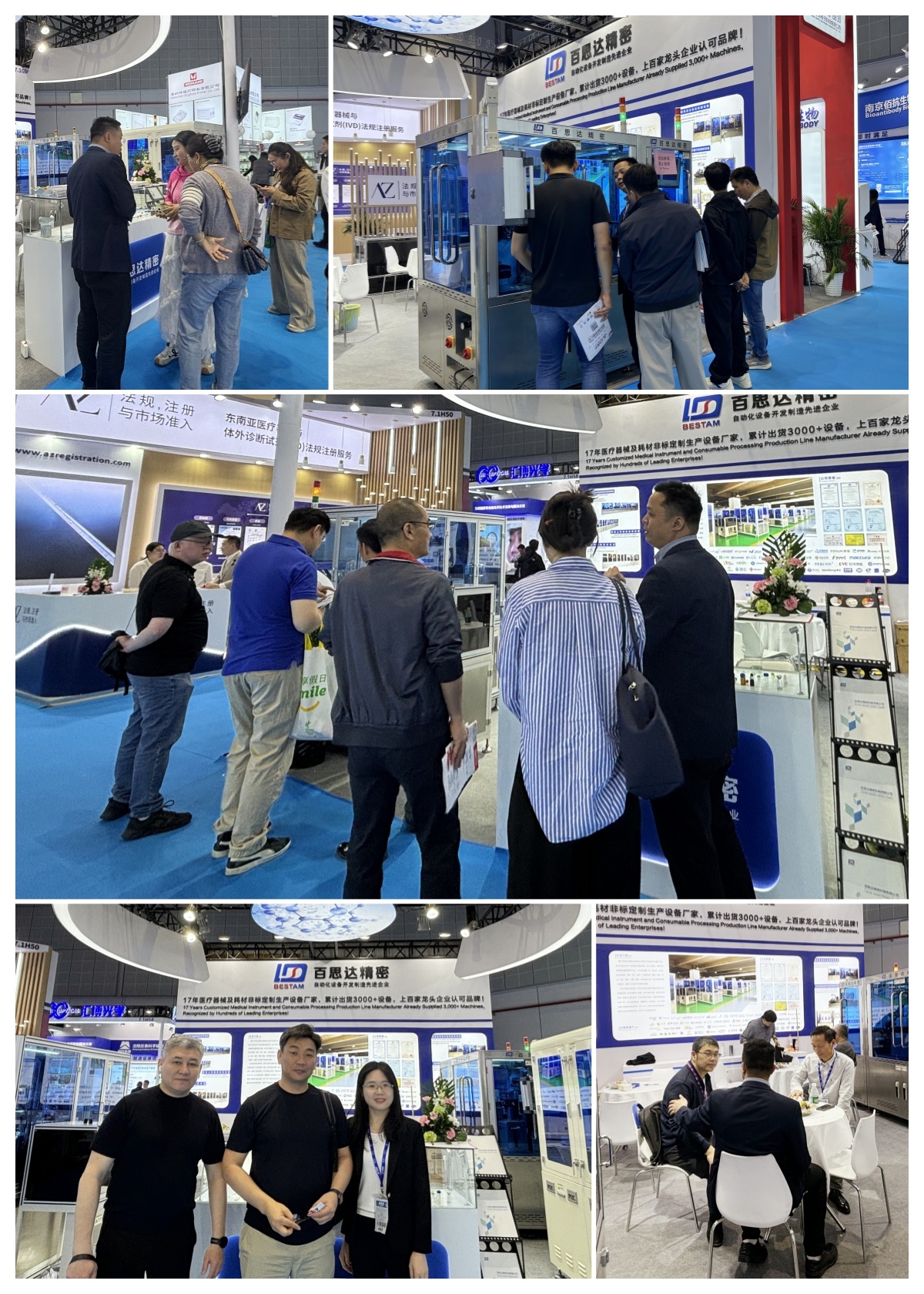

Busy booth, lively exchanges

02

CMEF is the intersection of innovation and development. At this exhibition, Baisida Precision Machinery not only showcased its technological strength but also actively engaged in in-depth exchanges with industry experts, peers, and potential customers. The company team detailed the research and development background and technical application experience of each equipment, emphasizing the practical application value of the equipment in medical equipment manufacturing, and reached a number of cooperation intentions with many partners. These collaborations have not only laid a solid foundation for the company's future development but also injected new vitality into the entire medical equipment manufacturing industry.

Digital Technology Summit

Warmly welcome your visit, let's talk about the future

03

In the future, Baisida will continue to increase R&D investment and launch more medical and in-vitro diagnostic manufacturing equipment to meet market demand.

Digital Technology Summit

At the same time, we are actively deploying the international market, striving to become a leading enterprise in the global medical equipment manufacturing industry, To contribute more to the development of the medical equipment manufacturing industry We sincerely invite our customers, friends, and industry colleagues to visit and exchange ideas at Baisida's 。 exhibition hall to discuss the future development direction of medical equipment manufacturing together. We look forward to working with you to create a better future! 在的展馆参观交流,共同探讨医疗设备制造的未来发展方向,我们期待与您携手共创美好未来!

Press recommend

Why is everyone promoting production equipment for standard card-type test cards, yet rarely mentioning equipment designed for pen-type test cards? That’s because pen-type test card production machines demand significantly higher technical expertise. Standard card-type equipment uses a simple, flat fixture arranged in a single line, while pen-type cards feature highly varied curved surfaces with dramatic differences in curvature—requiring precise alignment that must be achieved instantly to prevent gaps from forming. Moreover, the feeding process for pen-type cards is prone to misalignment, often leading to material stacking or even machine jams. And here’s another challenge: traditional 2D vision systems rely solely on "flat templates," so when they encounter the reflective surfaces or gradually changing patterns of pen-type test cards, they quickly "lose sight" altogether, resulting in a defect detection rate that starts at 2% or higher.

Jointly exhibiting at MEDICA 2025 in Germany—shining brightly on the international stage

On November 17, the world's most prestigious international medical event—the MEDICA 2025 International Medical & Healthcare Exhibition in Düsseldorf, Germany—began with a dazzling opening along the picturesque banks of the Rhine River.

Exhibition Preview | Bestar sincerely invites you to attend the MEDICA trade fair in Germany!

From November 17 to 20, 2025, MEDICA, the global benchmark for the medical industry, will make a grand debut in Düsseldorf. As a national-level high-tech enterprise specializing in precision manufacturing of biomedical machinery for 17 years, Huizhou Bestar Precision Machinery Co., Ltd. will showcase its cutting-edge in-vitro diagnostic technology solutions for the first time—stepping onto the international stage as a service provider (Hall 3, Stand H14)—and proudly present China’s “Made-in-China” innovation achievements, backed by 17 years of meticulous craftsmanship.

Precision is power: Precision Filling Equipment with Three-Way Valves

Traditional filling equipment has always faced three major challenges when handling high-viscosity and corrosive fluids: wall-adhesion losses erode product profits, fluctuating precision lowers yield rates, and cross-contamination poses significant quality-control risks. However, the three-way valve automatic filling system—centered around its advanced layered dynamic filling technology—redefines the standards for complex fluid handling. It’s as if equipping both laboratories and production lines with a "fluid GPS," ensuring that every drop of colloid, lysate, or biological reagent is delivered precisely to its intended destination, making layered filling a process that’s "zero stress" from start to finish!

Addressing industry pain points: The four major challenges in EP tube backend packaging—manual counting errors and omissions, blind spots in pneumatic sampling inspections, missed detection of visual defects, and downtime caused by switching between multiple specifications—have been tackled head-on by Bestar’s automated microcentrifuge tube packaging machine, which delivers four core solutions to ensure that every bag of centrifuge tubes achieves near-perfect results: "zero errors, zero missed defects, and zero human-induced inaccuracies."

The multi-variety, small-batch production model is causing Chinese IVD companies to suffer from chronic "blood loss"—leading to increased costs and reduced efficiency (such as expanded factory space, higher energy consumption in environmental control systems), a larger workforce, rising product defect rates due to inadequate cleaning practices, and extended equipment-changeover times. Against this backdrop, production and assembly equipment capable of seamlessly handling card-type or pen-type reagent cards of varying scales could be the key to breaking through these challenges! Bestar’s independently developed dual-channel assembly and packaging line for card-type or pen-type reagent cards represents a groundbreaking technological innovation that overcomes industry-specific technical barriers, delivering highly efficient, precise, and fully controllable testing solutions tailored for the life sciences sector!