How to choose the right robot in automated production

Release time:

2024-10-17 09:35

Source:

Today, the demand for automation is growing, and robots are becoming a key tool for improving efficiency and accuracy.

Many factories have relatively insufficient knowledge of robotics. Many factories are prone to fall into misunderstandings when introducing automation, such as thinking that full automation can be achieved only by purchasing a robotic arm. However, the robotic arm is only a basic component, and it is still a long way from a complete robot actuator.

Below we will share with you how to choose the right robot, analyze the gap between the robot arm and the complete robot system, and explore how to build an efficient automation system through reasonable design and integration.

The difference between a robotic arm and a robot

First, we need to clarify the difference between a robotic arm and a robot.

A robotic arm is an automated device designed to perform specific tasks. Its operation is based on pre-set procedures or inductive feedback mechanisms, and is suitable for highly repetitive tasks such as material handling and sample handling. In essence, it is a highly specialized tool.

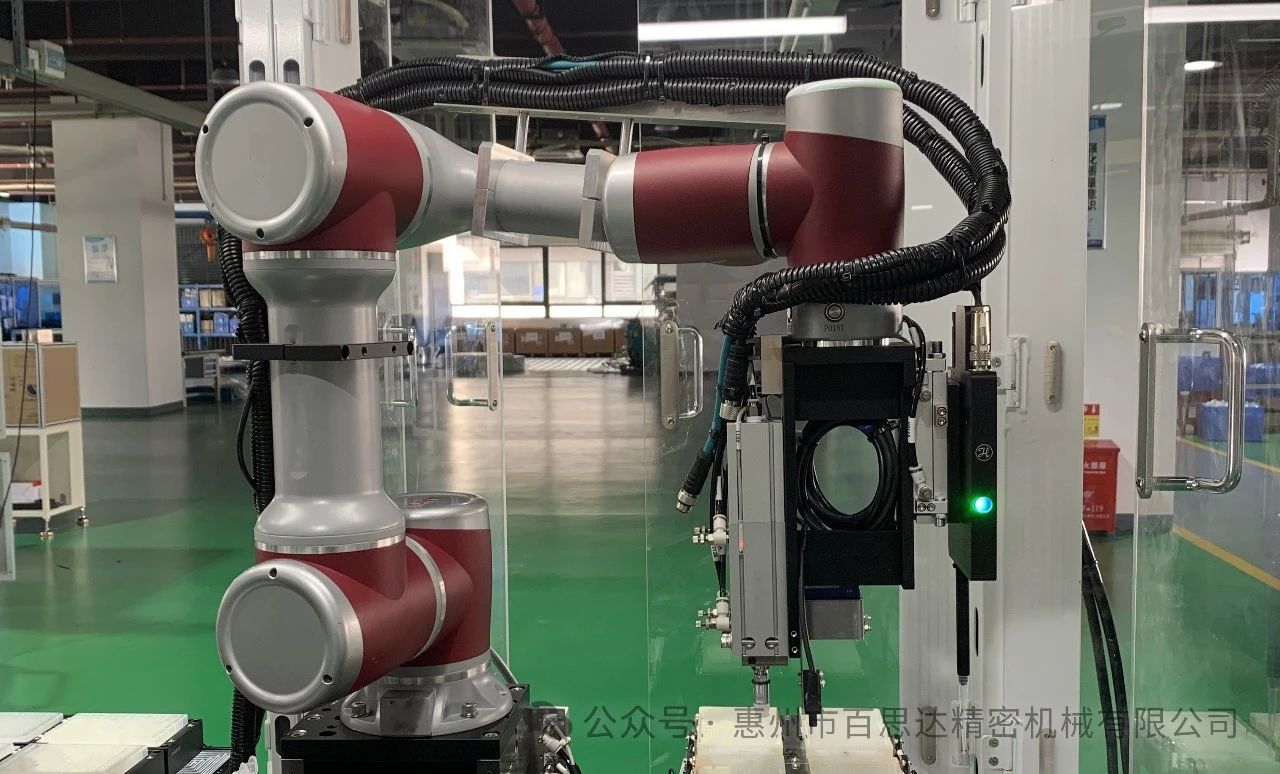

In contrast, robots are more complex, integrating multiple sets of components such as robotic arms, control systems, sensor systems and motion planning systems. They can not only complete predetermined tasks, but also adjust themselves according to environmental changes, which is suitable for more diverse Scenes.

How a robotic arm can be upgraded to a robot

From a robotic arm to a complete robotic actuator, there are still many key links to fill:

System integration:

In order to be a true robot, a robotic arm must be tightly integrated with multiple other subsystems-including control systems, sensor systems, motion planning systems, and more. The effective cooperation of each system is the key to ensure that the robot arm can accurately perform complex tasks.

Additional devices:

Robotic arms are often equipped with end effector such as grippers, grippers, and sometimes vision cameras and light sources to meet specific application needs. However, the custom design and manufacture of these accessories is usually beyond the scope of the robot arm manufacturer's service.

Support structure and motion system:

The robot arm needs a stable support structure to ensure the stability and range of motion of its operation. Many automation tasks also require additional moving structures, such as sliding rails or moving platforms.

Software and algorithms:

In order to achieve efficient operation in complex environments, the manipulator needs to be equipped with special software and intelligent algorithms. These algorithms are responsible for path planning, task scheduling, fault detection and self-correction to ensure their stable operation.

Debugging and optimization:

In order to ensure the performance of the robot arm in the actual operation to achieve the desired effect, it is necessary to carry out detailed debugging and optimization. This link is usually done by professionals, not within the scope provided by the robot arm manufacturer.

Important factors in choosing robots in factories

Task requirements:

When choosing a suitable robot, the specific application scenario should first be clarified. For example, high-precision robots may be required for precision tasks such as micro-liquid dispensing or fine sample handling, and load capacity and mobility may be considered when handling heavy objects or covering a wide area.

System integration capability:

Robotic arms are only part of the automation system. To realize a complete automation solution, system integration, additional device development, support structure design, and debugging and optimization are also required. Cooperation with professional automation integrators to ensure effective integration of individual components.

Price:

Within the budget, choose a robot system that is powerful but does not exceed the needs to ensure a reasonable return on investment.

The benefits of robots in production

A complete robotic system can bring many benefits in automation:

Increased efficiency:

Robots can perform repetitive tasks continuously and efficiently, thereby reducing manual labor time and costs, and significantly improving overall factory productivity.

Improve accuracy:

Precise control algorithms and feedback mechanisms are essential to ensure robot performance in high-precision tasks.

Reduce manpower dependence:

Robots can take on heavy, health-threatening and repetitive tasks, reducing the physical burden on employees and allowing them to focus on higher-value work.

Data collection and optimization:

Robots collect operational data in real time for plant process optimization and decision analysis, enhancing overall efficiency and accuracy. Choosing the right robotic system takes into account the actual needs of the plant, space constraints and system integration capabilities, as well as the budget. In view of the low level of understanding of robotics in factories, factories should pay special attention when selecting and manufacturing robots.

Work with professional automation integrators to ensure an efficient automation system. Through proper selection and design, the factory can greatly improve work efficiency, accuracy and flexibility, and move towards a more intelligent future.

Press recommend

Why is everyone promoting production equipment for standard card-type test cards, yet rarely mentioning equipment designed for pen-type test cards? That’s because pen-type test card production machines demand significantly higher technical expertise. Standard card-type equipment uses a simple, flat fixture arranged in a single line, while pen-type cards feature highly varied curved surfaces with dramatic differences in curvature—requiring precise alignment that must be achieved instantly to prevent gaps from forming. Moreover, the feeding process for pen-type cards is prone to misalignment, often leading to material stacking or even machine jams. And here’s another challenge: traditional 2D vision systems rely solely on "flat templates," so when they encounter the reflective surfaces or gradually changing patterns of pen-type test cards, they quickly "lose sight" altogether, resulting in a defect detection rate that starts at 2% or higher.

Jointly exhibiting at MEDICA 2025 in Germany—shining brightly on the international stage

On November 17, the world's most prestigious international medical event—the MEDICA 2025 International Medical & Healthcare Exhibition in Düsseldorf, Germany—began with a dazzling opening along the picturesque banks of the Rhine River.

Exhibition Preview | Bestar sincerely invites you to attend the MEDICA trade fair in Germany!

From November 17 to 20, 2025, MEDICA, the global benchmark for the medical industry, will make a grand debut in Düsseldorf. As a national-level high-tech enterprise specializing in precision manufacturing of biomedical machinery for 17 years, Huizhou Bestar Precision Machinery Co., Ltd. will showcase its cutting-edge in-vitro diagnostic technology solutions for the first time—stepping onto the international stage as a service provider (Hall 3, Stand H14)—and proudly present China’s “Made-in-China” innovation achievements, backed by 17 years of meticulous craftsmanship.

Precision is power: Precision Filling Equipment with Three-Way Valves

Traditional filling equipment has always faced three major challenges when handling high-viscosity and corrosive fluids: wall-adhesion losses erode product profits, fluctuating precision lowers yield rates, and cross-contamination poses significant quality-control risks. However, the three-way valve automatic filling system—centered around its advanced layered dynamic filling technology—redefines the standards for complex fluid handling. It’s as if equipping both laboratories and production lines with a "fluid GPS," ensuring that every drop of colloid, lysate, or biological reagent is delivered precisely to its intended destination, making layered filling a process that’s "zero stress" from start to finish!

Addressing industry pain points: The four major challenges in EP tube backend packaging—manual counting errors and omissions, blind spots in pneumatic sampling inspections, missed detection of visual defects, and downtime caused by switching between multiple specifications—have been tackled head-on by Bestar’s automated microcentrifuge tube packaging machine, which delivers four core solutions to ensure that every bag of centrifuge tubes achieves near-perfect results: "zero errors, zero missed defects, and zero human-induced inaccuracies."

The multi-variety, small-batch production model is causing Chinese IVD companies to suffer from chronic "blood loss"—leading to increased costs and reduced efficiency (such as expanded factory space, higher energy consumption in environmental control systems), a larger workforce, rising product defect rates due to inadequate cleaning practices, and extended equipment-changeover times. Against this backdrop, production and assembly equipment capable of seamlessly handling card-type or pen-type reagent cards of varying scales could be the key to breaking through these challenges! Bestar’s independently developed dual-channel assembly and packaging line for card-type or pen-type reagent cards represents a groundbreaking technological innovation that overcomes industry-specific technical barriers, delivering highly efficient, precise, and fully controllable testing solutions tailored for the life sciences sector!