How to choose the right robot in automated production

Release time:

2024-10-17 09:35

Source:

Today, the demand for automation is growing, and robots are becoming a key tool for improving efficiency and accuracy.

Many factories have relatively insufficient knowledge of robotics. Many factories are prone to fall into misunderstandings when introducing automation, such as thinking that full automation can be achieved only by purchasing a robotic arm. However, the robotic arm is only a basic component, and it is still a long way from a complete robot actuator.

Below we will share with you how to choose the right robot, analyze the gap between the robot arm and the complete robot system, and explore how to build an efficient automation system through reasonable design and integration.

The difference between a robotic arm and a robot

First, we need to clarify the difference between a robotic arm and a robot.

A robotic arm is an automated device designed to perform specific tasks. Its operation is based on pre-set procedures or inductive feedback mechanisms, and is suitable for highly repetitive tasks such as material handling and sample handling. In essence, it is a highly specialized tool.

In contrast, robots are more complex, integrating multiple sets of components such as robotic arms, control systems, sensor systems and motion planning systems. They can not only complete predetermined tasks, but also adjust themselves according to environmental changes, which is suitable for more diverse Scenes.

How a robotic arm can be upgraded to a robot

From a robotic arm to a complete robotic actuator, there are still many key links to fill:

System integration:

In order to be a true robot, a robotic arm must be tightly integrated with multiple other subsystems-including control systems, sensor systems, motion planning systems, and more. The effective cooperation of each system is the key to ensure that the robot arm can accurately perform complex tasks.

Additional devices:

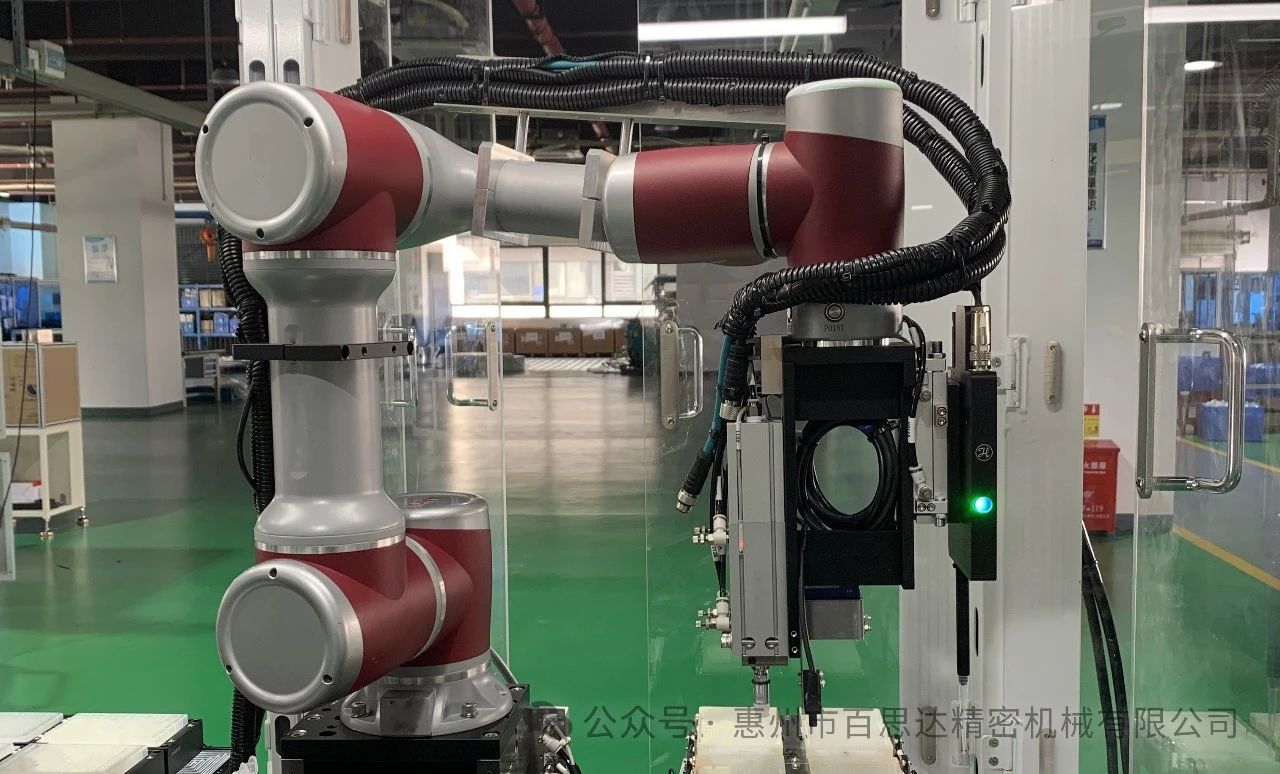

Robotic arms are often equipped with end effectors such as grippers, grippers, and sometimes vision cameras and light sources to meet specific application needs. However, the custom design and manufacture of these accessories is usually beyond the scope of the robot arm manufacturer's service.

Support structure and motion system:

The robot arm needs a stable support structure to ensure the stability and range of motion of its operation. Many automation tasks also require additional moving structures, such as sliding rails or moving platforms.

Software and algorithms:

In order to achieve efficient operation in complex environments, the manipulator needs to be equipped with special software and intelligent algorithms. These algorithms are responsible for path planning, task scheduling, fault detection and self-correction to ensure their stable operation.

Debugging and optimization:

In order to ensure the performance of the robot arm in the actual operation to achieve the desired effect, it is necessary to carry out detailed debugging and optimization. This link is usually done by professionals, not within the scope provided by the robot arm manufacturer.

Important factors in choosing robots in factories

Task requirements:

When choosing a suitable robot, the specific application scenario should first be clarified. For example, high-precision robots may be required for precision tasks such as micro-liquid dispensing or fine sample handling, and load capacity and mobility may be considered when handling heavy objects or covering a wide area.

System integration capability:

Robotic arms are only part of the automation system. To realize a complete automation solution, system integration, additional device development, support structure design, and debugging and optimization are also required. Cooperation with professional automation integrators to ensure effective integration of individual components.

Price:

Within the budget, choose a robot system that is powerful but does not exceed the needs to ensure a reasonable return on investment.

The benefits of robots in production

A complete robotic system can bring many benefits in automation:

Increased efficiency:

Robots can perform repetitive tasks continuously and efficiently, thereby reducing manual labor time and costs, and significantly improving overall factory productivity.

Improve accuracy:

Precise control algorithms and feedback mechanisms are essential to ensure robot performance in high-precision tasks.

Reduce manpower dependence:

Robots can take on heavy, health-threatening and repetitive tasks, reducing the physical burden on employees and allowing them to focus on higher-value work.

Data collection and optimization:

Robots collect operational data in real time for plant process optimization and decision analysis, enhancing overall efficiency and accuracy. Choosing the right robotic system takes into account the actual needs of the plant, space constraints and system integration capabilities, as well as the budget. In view of the low level of understanding of robotics in factories, factories should pay special attention when selecting and manufacturing robots.

Work with professional automation integrators to ensure an efficient automation system. Through proper selection and design, the factory can greatly improve work efficiency, accuracy and flexibility, and move towards a more intelligent future.

Press recommend

The 91st China International Medical Equipment Fair (CMEF) opened grandly in Shanghai on April 8, 2025. As an important platform for innovation and cooperation in the medical industry, this exhibition brought together medical elites from all over the world, with nearly 5,000 Brand enterprises showcasing tens of thousands of products, comprehensively demonstrating the latest achievements of the medical and health industry.

Recently, Huizhou science and technology circles ushered in a major event-the establishment of Huizhou Industrial Science and Technology and High-tech Association, and at the establishment meeting announced the top 20 award-winning enterprises with high comprehensive strength in Huizhou in 2024. Huizhou Best Precision Machinery Co., Ltd. won the list.

How to choose the right robot in automated production

Today, the demand for automation is growing, and robots are becoming a key tool for improving efficiency and accuracy. Many factories have relatively insufficient knowledge of robotics. Many factories are prone to fall into misunderstandings when introducing automation, such as thinking that full automation can be achieved only by purchasing a robotic arm. However, the robotic arm is only a basic component, and it is still a long way from a complete robot actuator.